THE FUTURE

of industrial heat

Engineered to

deliver.

Iron Fuel Technology™

Progress & roadmap

Protecting what matters

Iron Fuel Technology

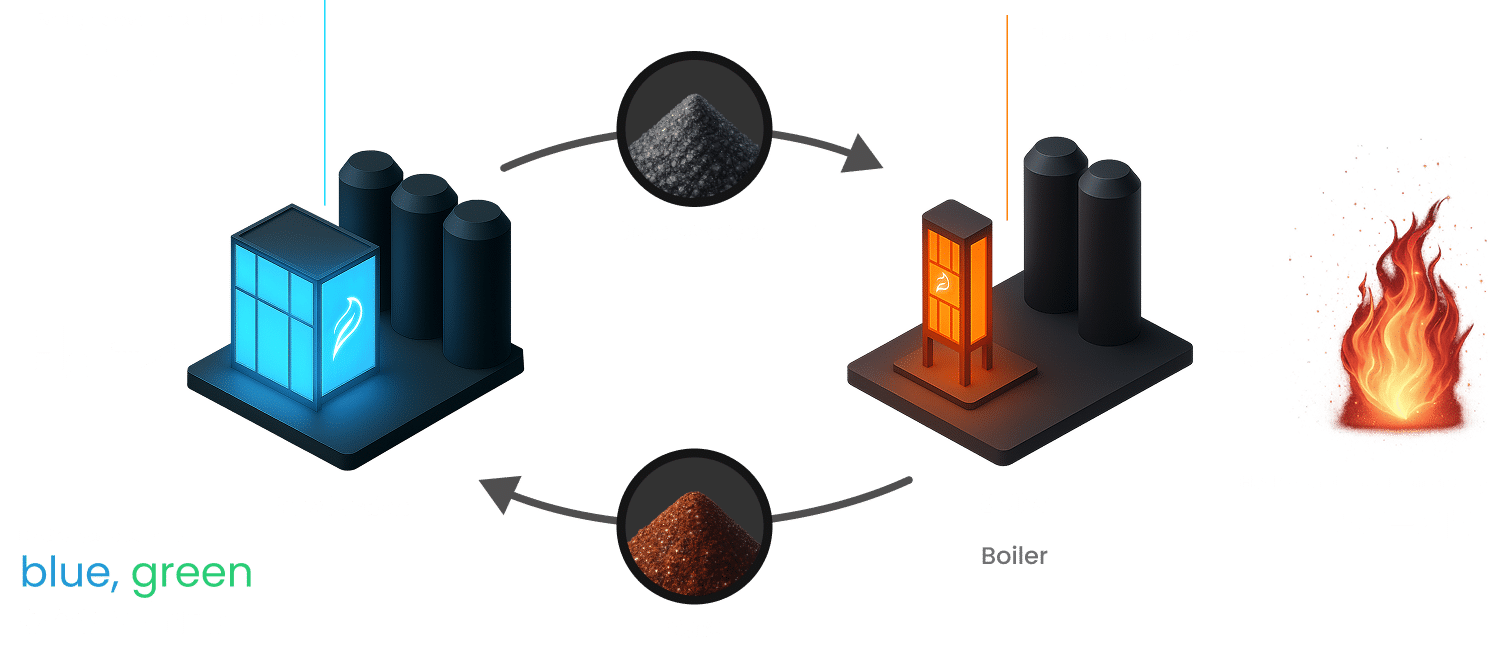

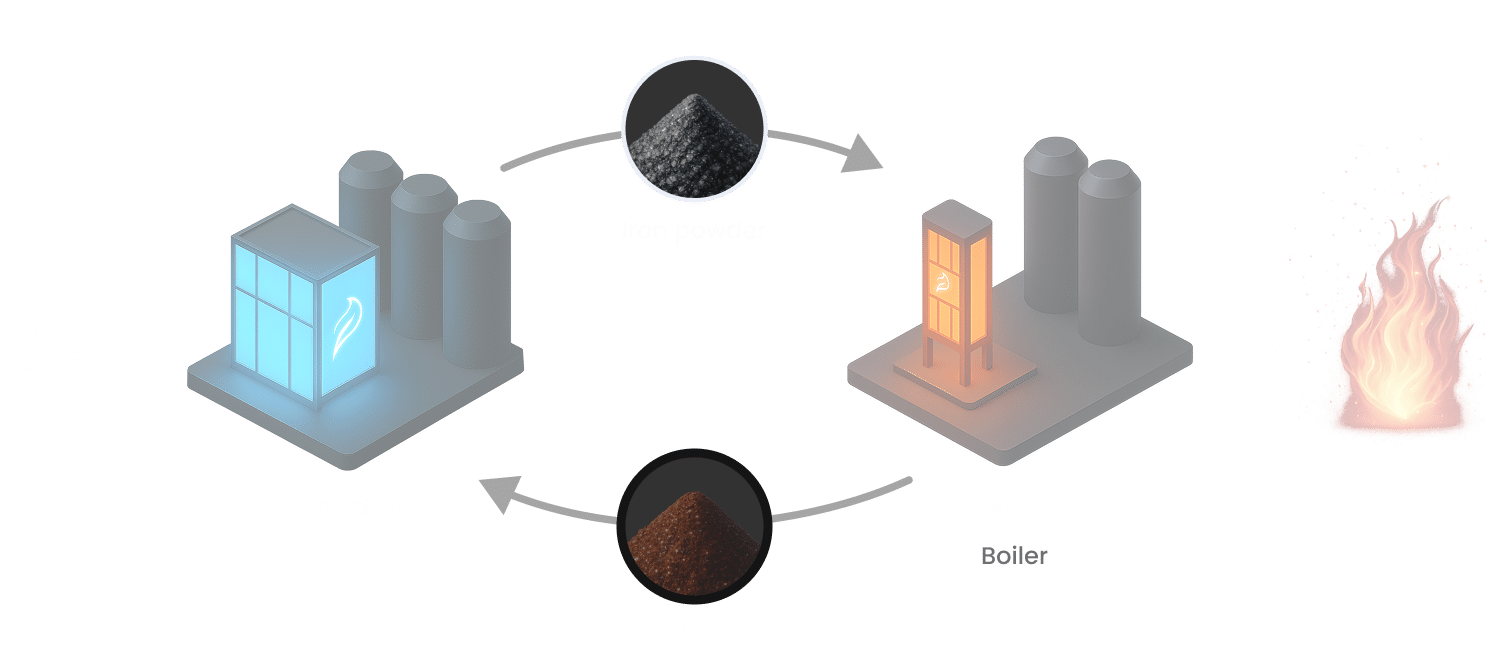

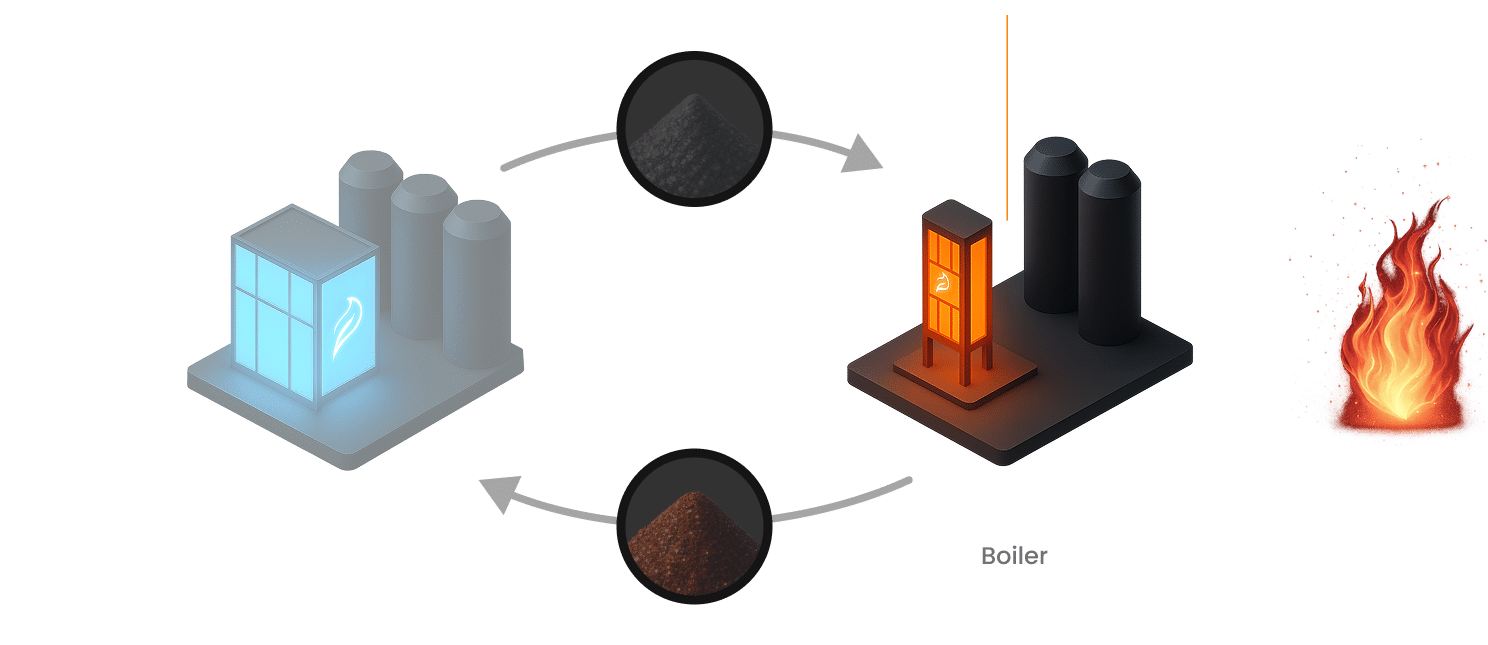

Iron Fuel

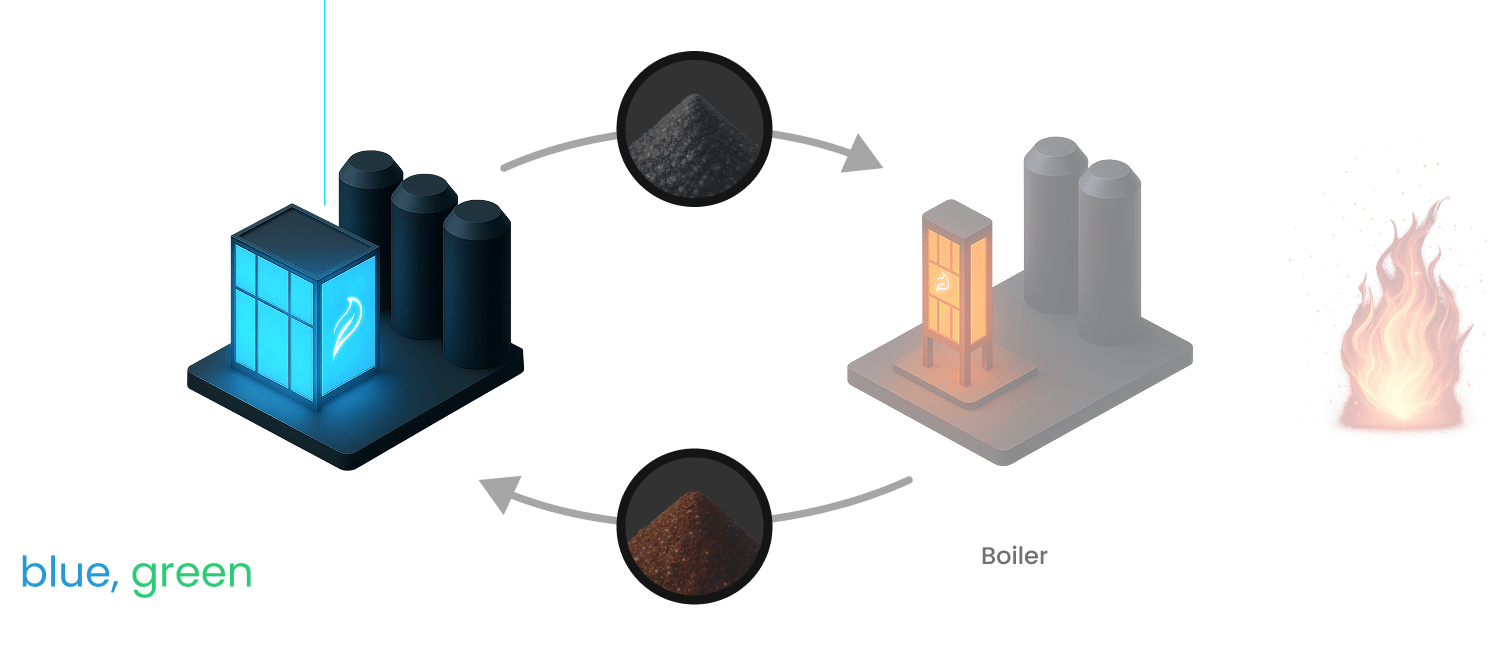

Step 1

Iron fuel (Fe) is stored and transported to our boiler locations, acting as a safe, solid energy carrier. The initial batch is sourced from the existing iron-powder market.

Iron Fuel Boiler

Step 2

In the boiler, iron fuel combusts with ambient air to create a flame of up to 2,000 °C. This heat produces steam, hot water, or hot air, with zero direct CO₂ emissions and ultra-low NOx emissions.

Iron Oxide

Step 3

The only by-product of combustion is iron oxide (rust). It is collected directly from the boiler chamber, safely stored, and transported to the production plant for regeneration.

Iron Fuel Production

Step 4

At the production plant, iron oxide is “recharged” into iron fuel using low-carbon hydrogen. Ready for the next cycle.

Iron Fuel development began at RIFT — spun out of Eindhoven University of Technology. First trailed in Helmond, where an Iron Fuel Boiler powered a district heating network under real-world regulatory conditions. This milestone proved the technology’s practical viability and marks the next step on our Technology Roadmap.

Innovating today. Impacting industry tomorrow.

Our solutionsR&D Tracks

Our R&D tracks underscore our commitment to continuous innovation — pushing Iron Fuel Technology toward scalable, high-impact clean energy.